Hochwertige 1,5-Liter-Labor-Sprühtrocknerausrüstung

Sprühtrockner im Labormaßstab eignen sich für die Produktion von Universitäten, Forschungsinstituten und Lebensmittel- und pharmazeutischen Chemieunternehmen.

Recently, we successfully completed a custom injection molding project for an overseas customer, demonstrating our ability to transform a physical sample into a fully matched molded product through professional engineering and testing.

The project began when the customer sent us an original plastic sample and clearly expressed their requirement: the final molded product must match the sample in appearance, dimensions, structure, and surface finish. This component would later be used in their production line, so consistency and accuracy were critical.

After receiving the sample, our technical team carefully evaluated its material type, wall thickness, draft angles, surface texture, and functional features. Based on this analysis, we proposed a complete solution including custom mold development and an injection molding machine suitable for stable production.

Using the customer’s sample as a reference, our engineers designed a dedicated injection mold. The mold structure, gating system, and cooling layout were optimized to ensure proper filling, dimensional stability, and repeatable quality.

Once the customer confirmed the mold design concept, we proceeded with in-house mold manufacturing, strictly controlling machining accuracy and surface treatment to achieve the desired product finish.

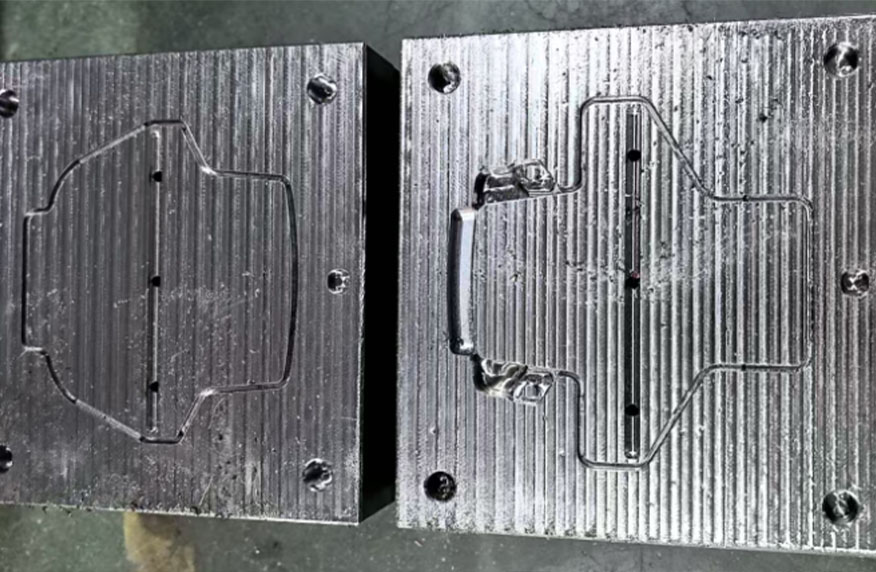

After completing the mold, we conducted multiple injection molding tests using our injection molding machine. Test samples were produced and directly compared with the customer’s original sample.

To ensure transparency, we prepared high-resolution detail comparison photos, focusing on:

l Overall shape and dimensions

l Edge details and surface texture

l Key functional areas

Based on the comparison results, minor adjustments were made to fine-tune the product until the molded parts matched the customer’s sample perfectly.

Once the comparison images and test results were sent to the customer, they carefully reviewed and confirmed that the molded samples were fully consistent with their expectations. With full confidence in both the equipment performance and mold quality, the customer placed an order for the injection molding machine together with the custom mold.

+86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529