In the industrial production process, solvents are an indispensable component, and the use and emission of solvents have become an increasingly serious environmental problem. In the process of pursuing environmental protection industrialization, how to use solvents efficiently and reasonably discharge waste solvents has become an important problem for various types of industries. The existence of solvent recovery machine solves this problem well, making the efficient conversion solvent becomes a possibility, which not only reduces the waste of solvent, but also reduces the pollution. The solvent recovery machine improves the environmental protection benefits and improves the economic benefits. This paper will illustrate the high efficiency of the solvent recovery machine from the principle of its application and the impact of different industrial fields.

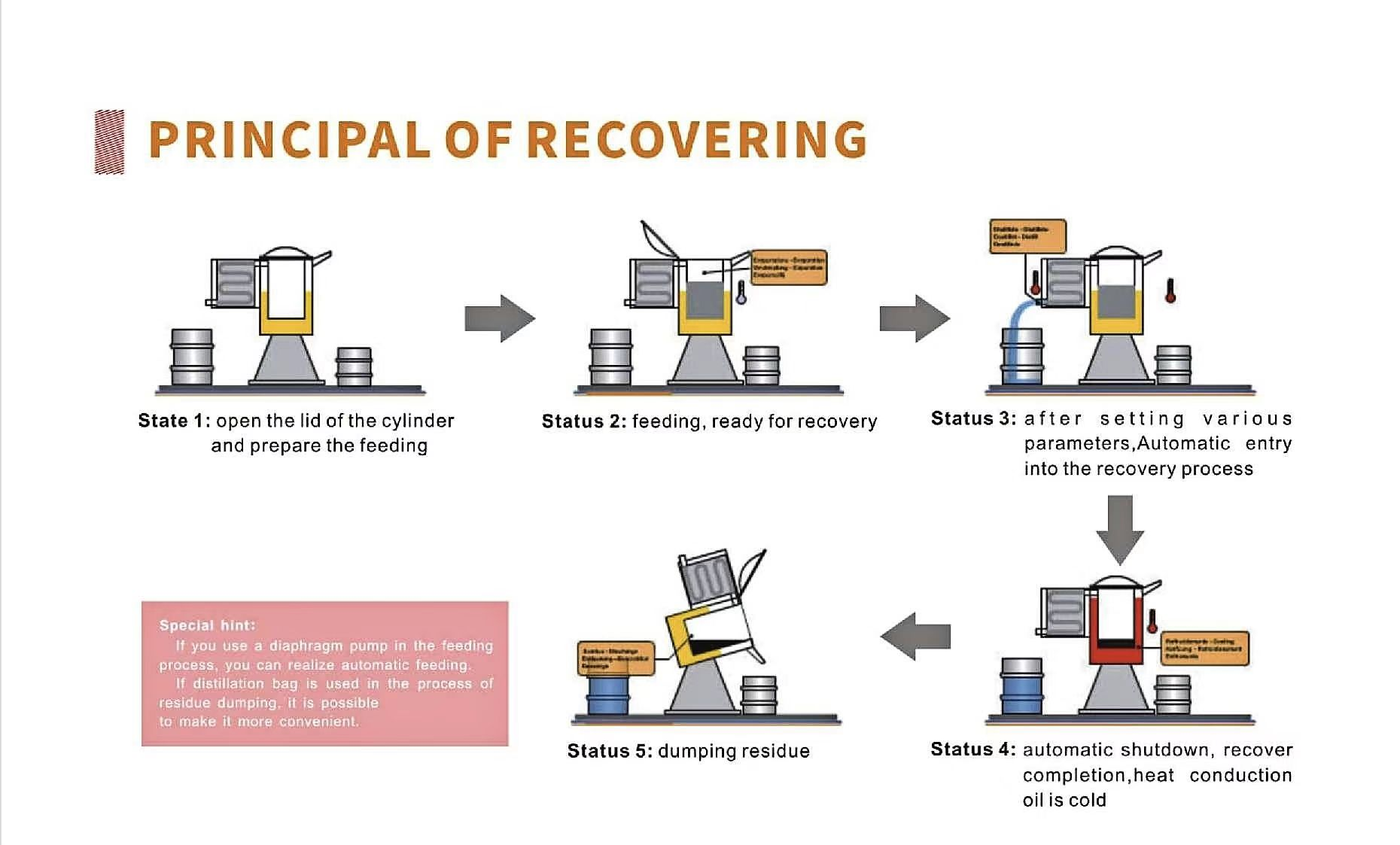

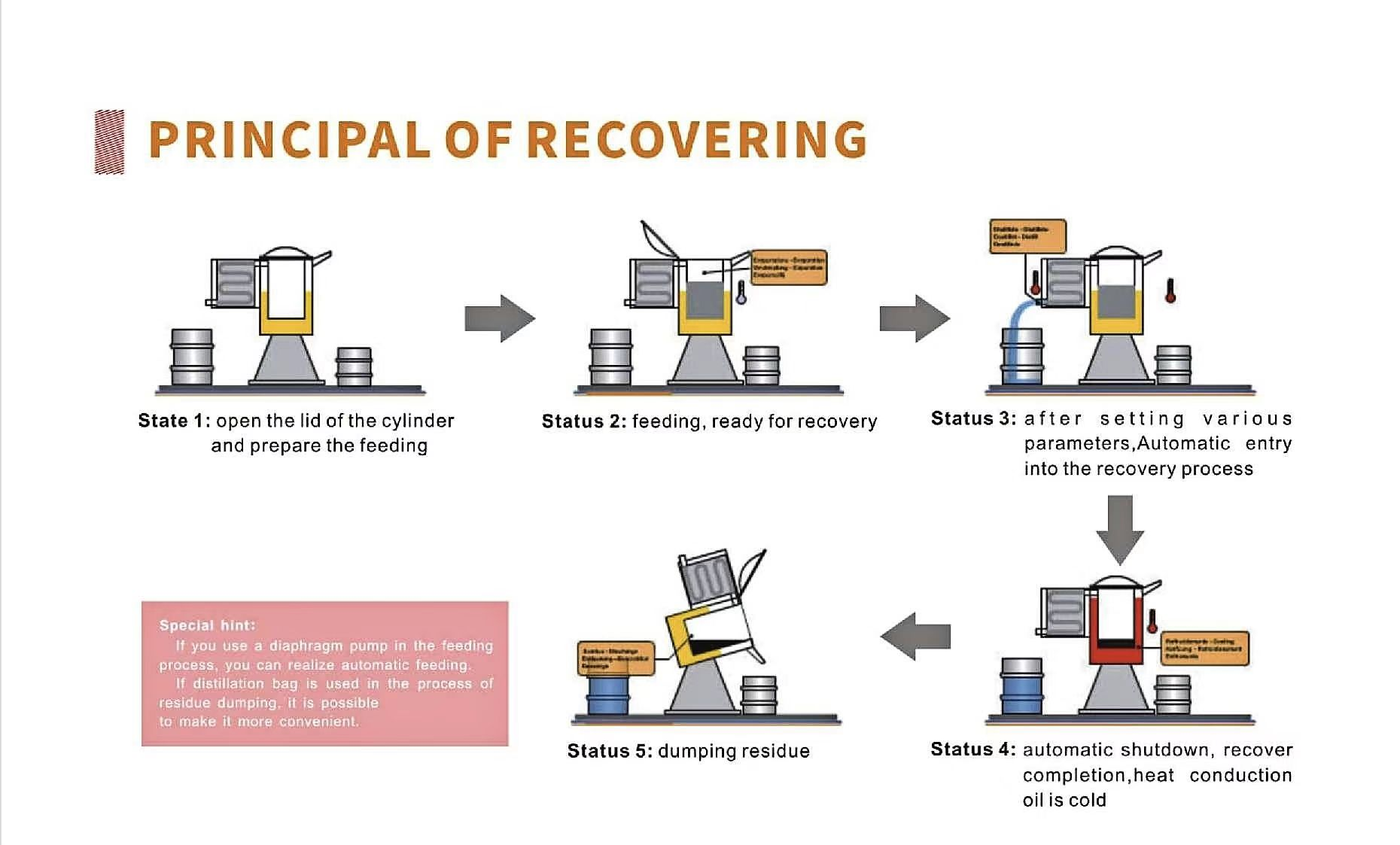

Principle of the solvent recovery machine

The solvent recovery machine uses the principle of distillation to evaporate the solvent into gas by heating, and then allows the vapor to enter the cooling system to liquefy and flow out, thereby recovering clean organic solvents. In this way, various contaminated organic solvents can be regenerated and recycled.

Application of solvent recovery machine in various industrial fields

Solvent recovery machine is suitable for automotive parts, electronic products, painted gold ornaments, precision casting, hardware manufacturing, artificial leather, plastic products, coating chemicals, LED products, tree limb shoes, LCD optical products, electroplating spraying and other industries.

For example, in the printing industry, solvent consumption is high and pollution is a serious problem. The application of printing waste chemical solvent recovery machine in this industry can effectively treat organic solvents discharged during the printing process, such as ink thinners, cleaning agents, etc. The solvent recovery machine separates harmful substances from waste solvents through its working principle. The purified solvent can be used again in printing production, thereby greatly reducing the demand for new solvents and significantly reducing the emission of volatile organic compounds. It efficiently converts waste organic solvents, thereby reducing pollution and has significant environmental benefits.

In the automobile industry, many parts of automobiles need to be painted during the manufacturing process, and some waste solvents will be generated during the painting operation. These used organic solvents have a variety of organic impurities and reduced purity. Waste solvents are not allowed to be discharged directly and must be treated. Most of the waste organic solvents are highly toxic, flammable, explosive, corrosive, volatile or reactive, which are extremely harmful to the environment and human health, so they are listed as a type of hazardous industrial waste. However, among the many waste organic solvents, most of them have a high recycling value. Automobile industry equipment solvent recovery machine provides a method for recycling waste solvents in the automobile industry. It performs multiple distillation operations on waste solvents to effectively realize the recovery of waste solvents. In addition, during the distillation process, it can prevent the colloid material from adhering to the inner wall of the distillation unit, affecting the normal distillation operation. Thus, a win-win situation of environmental protection and economic benefits is achieved.

Benefits of Solvent Recovery Machine

Safety and environmental protection: Waste organic solvents generated in industrial production are toxic and flammable liquids, which are extremely harmful to the environment and human life and health, and have also hindered the development of environmentally friendly enterprises. Using our solvent recovery machine during the use and recovery of solvents, measures are taken to reduce the emission of volatile organic compounds (VOCs) to reduce the impact on air quality. This not only reduces the factory's pollution emissions, but also provides employees with a safer working environment, which has good benefits for coexistence with the environment and humans.

Economic benefits: The solvent recovery machine recycles organic solvents. Our solvent recovery machine has a solvent recovery rate of up to 95%, which greatly reduces the production cost of the enterprise. The recycling and reuse of organic solvents improves the economic benefits of the enterprise. A good quality solvent recovery equipment improves the efficiency of all aspects during use and enhances the economic value of the solvent recovery machine.

Work efficiency: The new fully automatic solvent recovery machine has largely overcome the shortcomings of traditional recovery machines. It does not require too much manual supervision of the equipment during operation, saving labor costs. The fully automatic solvent recovery machine overcomes the shortcomings of traditional solvent recovery machines that the extracted solvents are difficult to be widely used due to low purity, and improves the purity of the solvent.

+86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529